|

|

|

| |

|

|

|

|

|

|

- (1)

- (4)

- (27)

- (4)

- (4)

- (45)

- (9)

- (2)

|

|

| |

|

|

Build Your Online Product Catalogs?

| Product Name: |

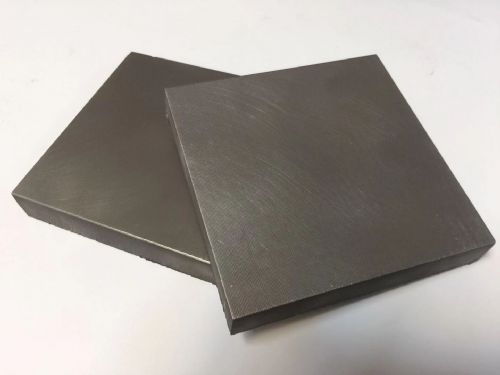

Titanium Forging Block From TOPTITECH

|

| Supply Ability: |

100000000 pieces |

| Related proudcts |

block, titanium forging, toptitech, |

| Specifications |

Customized |

| Price Term: |

CIF |

| Port of loading: |

door to door |

| Minimum Order |

1 |

| Unit Price: |

USD5-150/piece |

|

Product Introduction

Titanium offers many design and engineering advantages, including corrosion resistance, high strength-to-weight ratio, and ease of forming. Titanium forgings mainly have three shapes: titanium block, titanium ring and titanium cube.

Titanium has low density (4.51KG/M3), high melting point (1660℃), strong corrosion resistance, high specific strength, and good plasticity. Titanium has many excellent characteristics such as light weight, high strength, strong heat resistance, and corrosion resistance. Promising new structural materials. Titanium not only has very important applications in aviation and aero***ce industries.

Product name: titanium block, titanium cube, titanium forging

Material:

Domestic: TA1, TA2, TA3, TA4, TA9, TA10, TC4;

American Standard: GR1, GR2, GR3, GR4, GR5, GR7, GR11, GR12, GR23;

National standard: GB/T16598-1996 Ti 6Al 4V, Ti-0.2Pd, Ti0.3Mo 0.8Ni, T3AI 2.5V, Ti 6AI 4V ELL

American Standard: ASTM B348, ASTM B381, AMS 4928

Specifications

Outer diameter ¦Õ200-400*inner diameter ¦Õ100-300*height 20-120

Outer diameter ¦Õ400-700*inner diameter ¦Õ150-500*height 40-250

Outer diameter ¦Õ700-1500 *inner diameter ¦Õ300~1200*height 40-600

Features

1. Anti-pressure;

2. High temperature resistance;

3. Anti-corrosion;

4. Professional customization.

Production process

Forging, die forging, rotary forging, precision forging, welding, testing, tensile strength testing, hardness testing, chemical composition testing, ultrasonic testing, radiographic testing, penetrant coloring testing.

Surface treatment: car light, chamfering

Surface quality: the surface roughness Ra value of the two end faces should not be greater than 3,2l¦Ìm (subject to meeting the requirements of ultrasonic testing), the surface roughness Ra of the inner and outer sides should not be greater than 12.5¦Ìm (ultrasonic flaw ***ection is required for the outer peripheral surface When Ra should not be greater than 3.2¦Ìm), the chamfering radius is |

| Company: |

Baoji YingGao Metal Materials Co.,ltd.

|

| Contact: |

Ms. Karry Kang |

| Address: |

1502, Block A, Chuang Yi Building No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China |

| Postcode: |

721000 |

| Tel: |

86 19 992203758 |

| Fax: |

|

| E-mail: |

|

|

|